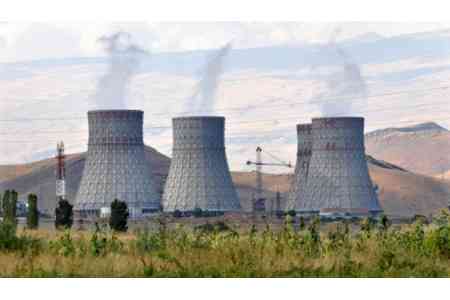

ArmInfo. The preparatory activities for annealing of the reactor vessel metal are started at the ANPP in the framework of the contract concluded with the Rusatom Service JSC, the press service of ANPP reports.

The representatives of the Novovoronezhatomenergoremont company, the branch of the Atomenergoremont JSC, have been at the ANPP since November 24, 2020, to participate in the activities aimed at assembling the facility for remedial thermal treatment (annealing) of the ANPP Unit 2 reactor vessel metal. Annealing is the most effective method of metal recovery. With use of annealing facility the reactor vessel is heated up to 4750 C, held up to 150 hours, and after that slow cooling down takes place. This process allows restoring the initial performance properties of the reactor metal for 80-85%.

This technology of annealing was successfully applied at many WWER-440 NPPs. During the ANPP 2021 scheduled outage the reactor annealing will be implemented securely facilitating the Unit 2 safety improvement and life extension.

To note, in 2021, a large amount of work is to be done at the Armenian NPP. In particular, recovery annealing of the reactor vessel will be carried out, the emergency core cooling system and the reliable power supply system will be modernized. A few days ago, a unit for the reduction annealing (heat treatment) of the reactor vessel metal was delivered to the Armenian NPP. The NPP will be prepared for the final part of the life extension work, which will take place in 2021. It is in the next year that the reactor will be annealed, which will allow the reactor to return to its original state by 80-85%. The procedure will be carried out by several organizations, each of which is responsible for its own area of work.